1

/

of

3

Tuhafiyeciniz

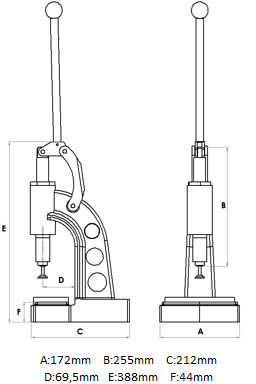

4125 DKP Manual Press

4125 DKP Manual Press

Regular price

6,093.95 TL

Regular price

Sale price

6,093.95 TL

Unit price

/

per

Tax included.

Shipping calculated at checkout.

Couldn't load pickup availability

- Universal Press 4125K

It has its own desk, which is very useful and easy to use. You can place and use it on any table without screwing it in.

Van awnings, touristic and commercial tents, curtains, advertising posters, etc. It is a large diameter eyelet press for You can easily attach and apply eyelets including size 66 (40mm).

Areas where you can use the press:

For cloth covering button in clothes, garments,

- Riveting, (rivet) for lighter

- For jeans buttons,

- for eyelet

- For drills and knives

- Drive type: Mechanical (manual)

Use type: Universal

Pressing force: up to 1300 kg/cm

Print Level: Professional (Ideal for high-volume medium to large production)

Features:

- Piece Height: 78cm

- Eyelet Hole:Ø 9 mm

- Dimensions: 170 x 220 x 780

- Weight: 10.5 Kg.

- Material: Cast Iron + Steel

- Production: Turkey

User guide:

Carefully read all instructions and warnings in this user manual. This manual contains important information about the safe installation, use and maintenance of your product, and warnings for you to get the most out of your device.

Keep this manual in a safe and easily accessible place for future use.

DKP 4125 BUTTON PLATING PRESS USAGE AREAS:

- marking automotive,

- printing and cosmetics

- drilling,

- stapling,

- skirt bending,

- bearing ramming,

- You can use it in your works such as cold seal.

- You can use it in capsule button in textile, in fabric covering.

NOTE: PLEASE AVOID THE SECTION TO BE PRESSED WHEN YOUR MACHINE IS WORKING.

KEEP AWAY OR GET HELP FROM A METAL OBJECT.

Technicial Specifications:

- Piece Height: 78cm

- Eyelet Hole:Ø 9 mm

- Dimensions: 170 x 220 x 780

- Weight: 10.5 Kg.

- 14 kg with table weight.

HOW SHOULD PERIODIC MAINTENANCE BE DONE?

DAILY MAINTENANCE:

•The surface of the work table should be cleaned of chips and material residues that may occur.

•Check the stability of your mold and tighten it in case of loosening.

MONTHLY MAINTENANCE:

• If there are any loose bolts, they should be tightened again.

• Lubricate the impacting shaft with a very small amount of thin oil.

Paylaş